DESIGN PROCESS

~Materials Testing & Safety

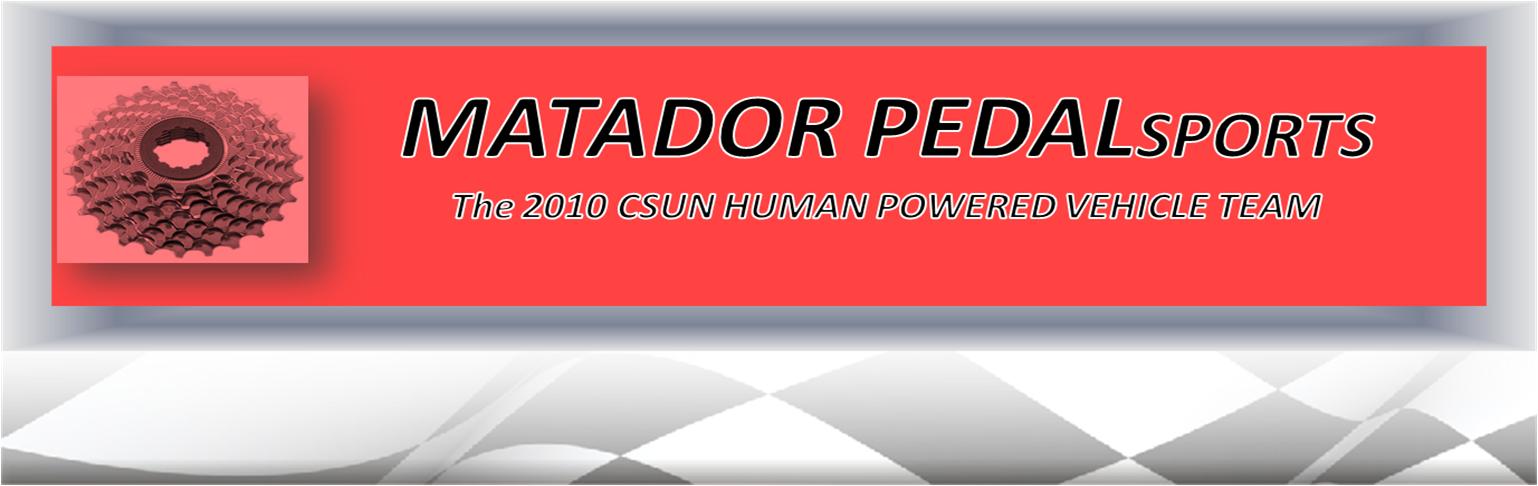

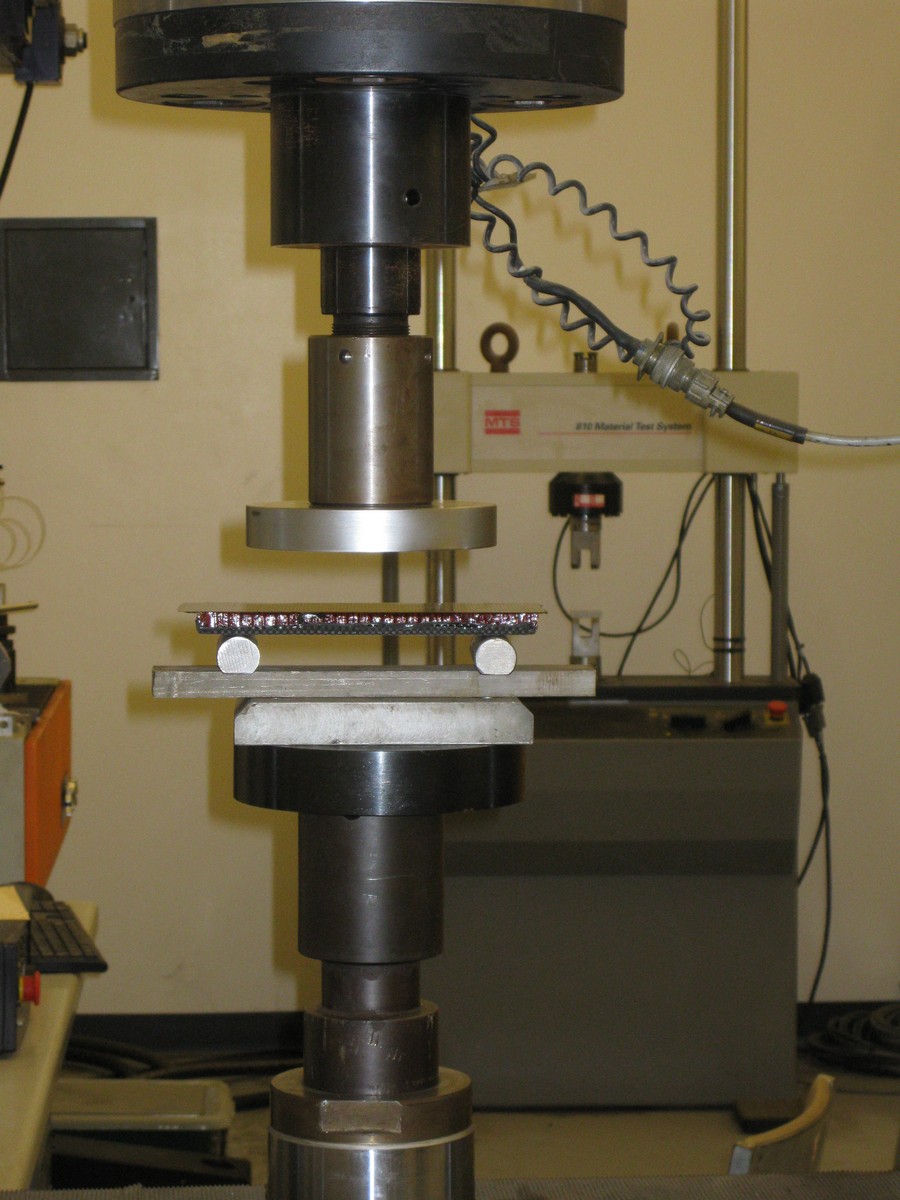

Testing the compressive strength of various composite bellypan materials in 4-point bending. Shown above with a 1/4" thick nomex core and several plies of carbon fiber adhered to the top and bottom of the test sample.

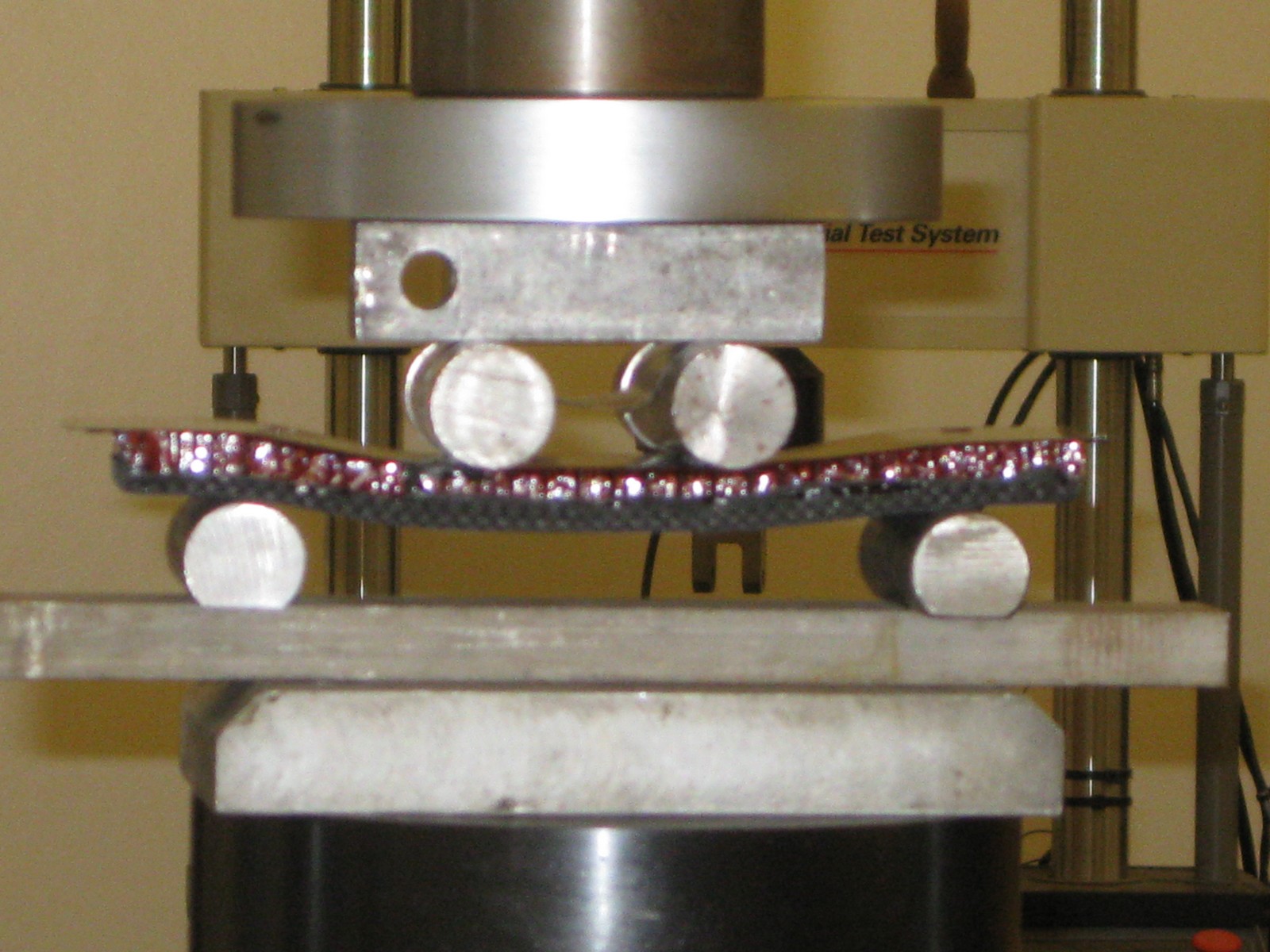

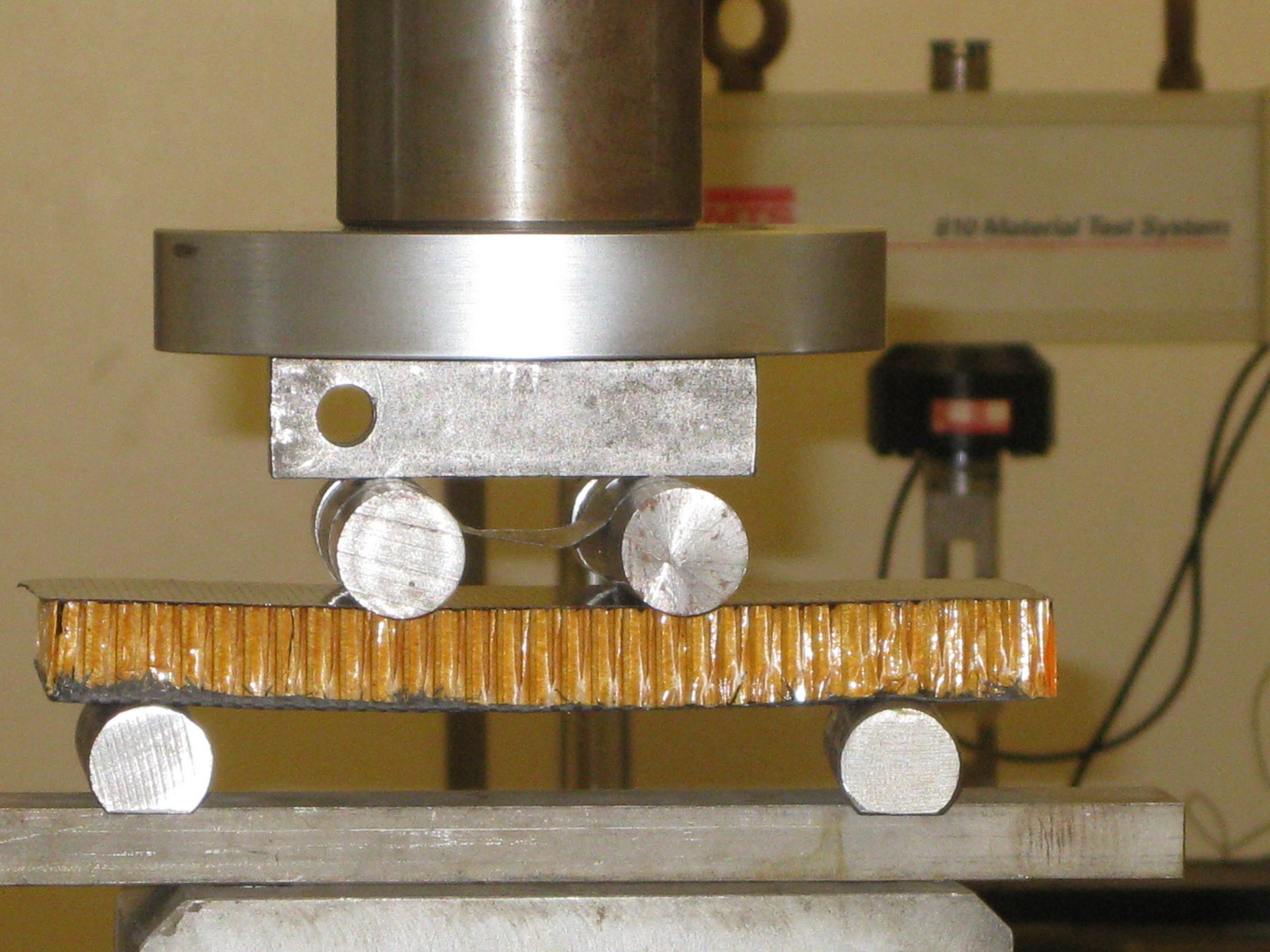

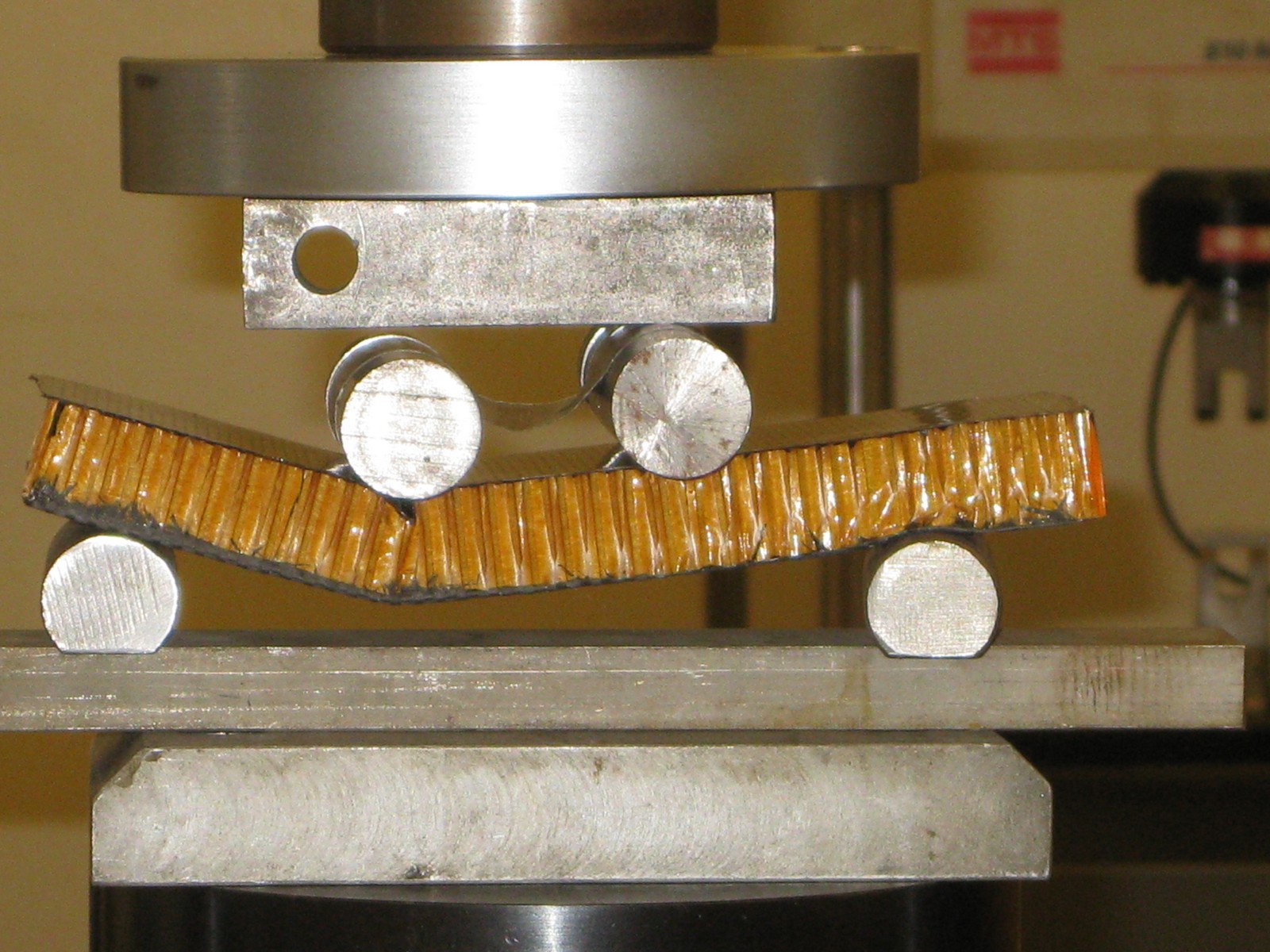

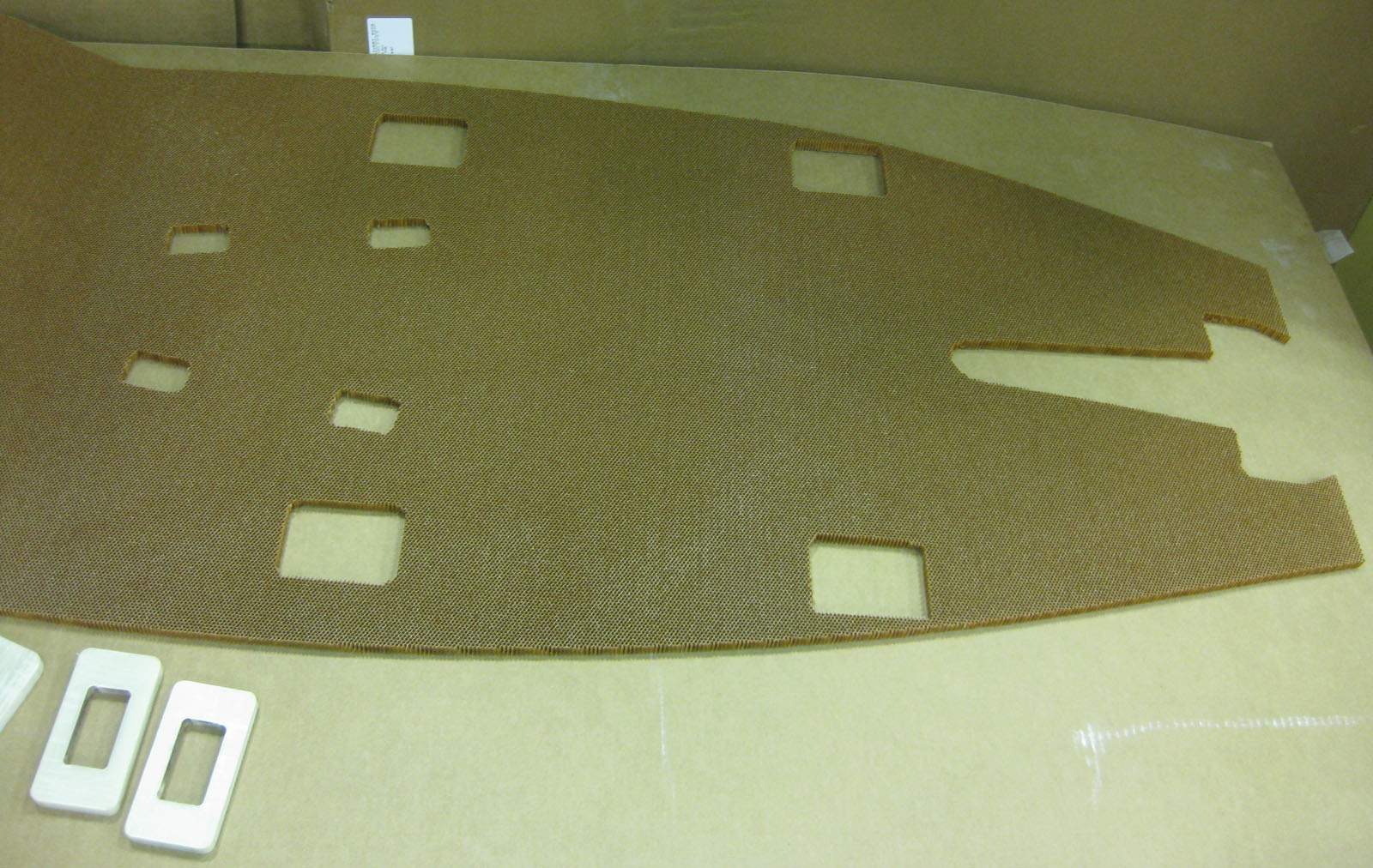

Shown above with a 1/2" thick nomex core and several plies of carbon fiber bonded to one another with a high-strength epoxy resin.

4-point bending machine. Also shown is a compressed composite material sample used for analysis purposes, after having been put through a 3-point bending test.

Shown direclty above from left to right are samples of various composite bellypan material arrangements that underwent strenuous 3-point of 4-point bending test. A composite core of Nomex-honeycomb, used in our core is also show in the bottom right.

Shown above is the podded insert that we tested with the shown cylindrical polymer block for strength and break testing. These two aluminum podded inserts, bonded to the composite carbon-fiber and honeycomb sample with a high-strength epoxy were able to withstand 192 ft-lb of vertical force on them, before beginning to fail.